The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Hamer Brand 2400 VBP Valve Bag Placer

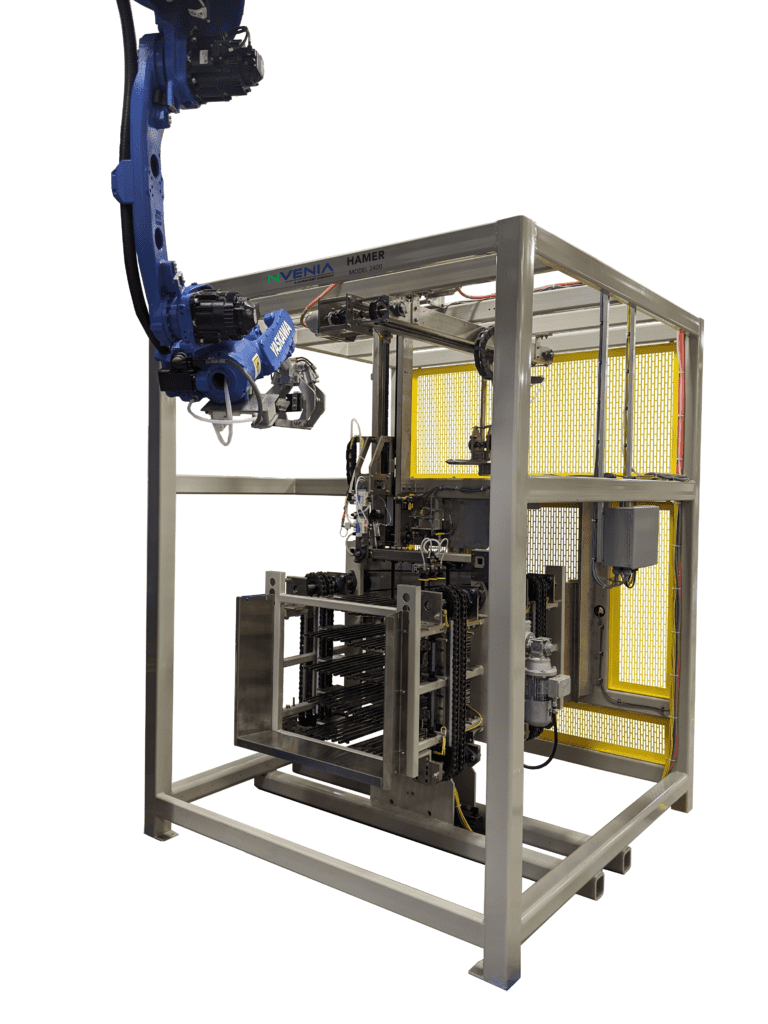

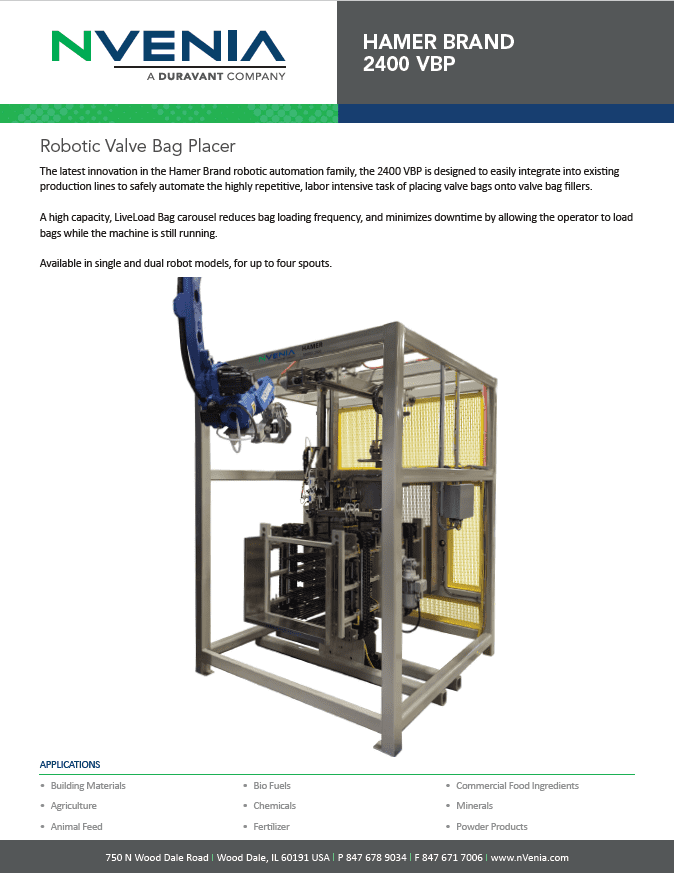

Our Hamer Brand 2400 VBP Valve Bag Placer provides automated placement of a wide variety of valve bags onto most valve bag filler machines available on the market today. Easily integrated into existing or new production lines, its modular design, single or dual robot system configurations, and extended cabling allows the 2400 VBP to be implemented in various layouts, providing the flexibility needed to meet your performance and facility requirements. Valve bags are utilized in multiple industries including building materials, chemicals, and minerals to package fine/dusty powders, granules, pellets, or mixes/blends of material types.

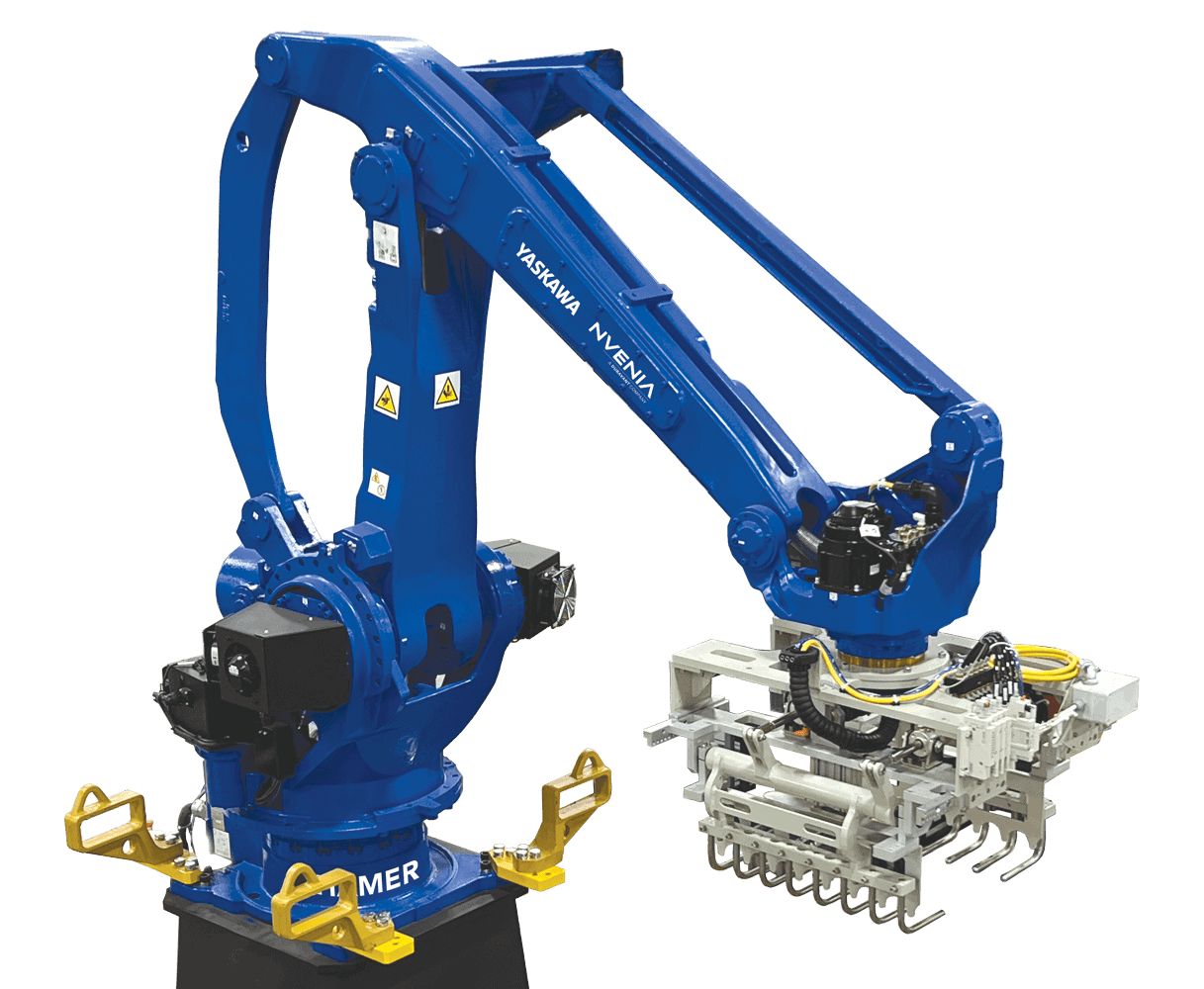

The 2400 VBP utilizes a 6-axis robot to reliably and efficiently select each bag and place it on the appropriate filler valve. The high capacity carousel allows for nearly double the capacity of traditional conveyorized bag feeding. The unique design of the carousel is arranged in a dual-sided 5 rack magazine which reduces the facility footprint. The LiveLoadTM carousel feature allows an operator to safely reload one side of the carousel racks without interrupting the picking and placing operation. This maximizes uptime and improves overall operational efficiency.

The Model 2400 VBP is available in single or dual robot configurations and can place bags on up to six filling spouts. It can accommodate a wide variety of bag types and sizes – seamlessly switching from one bag type/size to the next – further improving operational efficiency.

Are you interested in this product?

We are here to help.

Features

- High-speed Yaskawa GP12 6-axis robotics with Allen Bradley PLC control to maximize production output

- Compact robot controller to minimize facility footprint

- High-Capacity bag carousel to reduce frequency of empty bag re-loading

- Vertical, 5-rack bag magazines to optimize facility footprint

- LiveLoadTM carousel feature continues robotic bag placements while operators safely re-load empty bags to maximize production output

- Access door with interlock control and wire mesh fencing to provide user safety

- Servo controlled motors for precise, repeatable results

- Modular design with extended cable lengths for flexibility in facility layout

- Heavy-duty tubular steel frame and steel motor mounts protected by highly durable powder coat finish or nickel plating for long life in demanding plant environments.

- Ethernet Connectivity for remote troubleshooting

- Allen-Bradley MobileViewTM Handheld Color, Touchscreen User Interface with 10-meter cable length optimizes operator performance

- Soft shutdown of controller protects critical data in the event of power failure (UPS)

- Left or Right Hand Valve Orientation (assembly at time of purchase)

- NEMA 12 Electrics

Standard Specs

Standard Specs

Machine Dimensions

Bag Carousel:

105″ H x 84″ W x 80″ L

Speed

Single Robot – Up to 20 Bag Placements Per Minute (system configuration and bag type dependent) / Up to 3 spouts

Double Robot – Up to 37 Bag Placements Per Minute (system configuration and bag type dependent) / Up to 6 spouts

Bag Types

- Multi-wall Paper

- Multi-wall Paper w/ PE Inner Film

- Natural Kraft

- Plastic – “POLY”

- Block Bottom

Bag Sizes

- Width: 13″ to 20.5″

- Length: 14″ to 22.5″

Valve Compatibility

- Valve Width: 3″ to 8″

- Valve Orientation: Left Hand or Right Hand

Electrical Requirements

Single Robot – 460 VAC, 3 PH, 60 HZ, 32.5 A

Double Robot – 460 VAC, 3 PH, 60 HZ, 65 A

Air Requirements

Single Robot – 3.3 CFM @ 85 PSI (clean and dry air)

Double Robot – 6.6 CFM @ 85 PSI (clean and dry air)

Accessories

Accessories

OPTIONS:

- Additional Safety / Guarding Options

- Dual Robot

- Spare Parts Kits